In 1930, Phil Young stood on the 18th green at the Country Club of New Bedford, staring in disbelief as his short putt veered wildly off line. Most golfers would’ve cursed, maybe tossed their putter, and headed to the bar. But Young was an MIT Class of 1909 graduate with “an innate curiosity” and zero patience for unexplained failures. So naturally, he did what any self-respecting engineer would do—he convinced his playing partner, Dr. Bonner, to open his office so he could X-ray the golf ball.

What Young discovered was equal parts fascinating and infuriating. His ball, along with several others, had cores that were wildly off-center. His was out of round and asymmetrical. “No wonder it hooks and slices,” he told Dr. Bonner, adding with characteristic confidence, “If I could make a round ball with a stable core, I could sell a few.”

Young had founded the Acushnet Process Company in 1910, initially focused on de-resinating latex and supplying rubber to American industries. But after his X-ray revelation, he split the company into two divisions—Rubber and Golf. The Golf division, established in 1932, would become Titleist, and Young’s engineering philosophy would echo through nearly a century of innovation. A colleague once said of Young: “If it doesn’t work, he will take it apart to find out why, and if it does work, he will take it apart to find out what makes it work.”

That relentless curiosity wasn’t just talk. In 1935, Young invented a golf-ball driving machine that could be transported across the country. Here’s the kicker: Acushnet’s first patent in 1936 wasn’t for a golf ball at all—it was for that dual pendulum testing machine. Young understood something profound: before you could build the best ball, you needed to build the best tools to test it.

Flash forward seventy years to October 2000, and the stage was set for one of golf’s most dramatic equipment shifts. The Invensys Classic in Las Vegas was just another fall tournament on the PGA Tour, but what happened there would become legend.

Billy Andrade arrived in Vegas in rough shape. At 36, he’d missed the cut in 18 of his 28 tournaments that year. For the first time since 1988, he was headed back to Q-School—professional golf’s version of purgatory.

Then he hit Titleist’s new Pro V1 during a practice round.

“I’m 100 percent using it this week,” Andrade declared. “That’s how good it is.”

He wasn’t alone. Forty-seven players in the field switched to the Pro V1 that week—the largest pluralistic shift of equipment at one event in golf history. Andrade shot 67-67-63-67-68 to win by one stroke, saving his season and jump-starting an entire second phase of his career.

The Pro V1 delivered something players had always wanted but assumed was impossible: a solid construction ball that gave you both distance AND feel. The wound balls offered feel but lacked distance. The solid balls offered distance but felt like rocks. The Pro V1 did both, thanks to its revolutionary solid core, multi-layer construction, and cast urethane cover.

What followed was nothing short of a phenomenon. In early 2001, scoring records fell like dominoes. Brad Faxon at the Sony Open. Mark Calcavecchia at the Phoenix Open. Davis Love III at Pebble Beach. All playing Pro V1s. By March 2001, it became the best-selling ball in golf, and it hasn’t relinquished that position for a single month in twenty-five years.

But Vegas didn’t happen by accident. Behind that historic week was what insiders call “the 100-Man March”—one of the gutsiest validation campaigns in sports equipment history.

In summer 2000, Titleist’s leadership knew they had something special. But they needed confirmation from the world’s best players under real tour conditions. So CEO Wally Uihlein, along with Bill Morgan, Mac Fritz, Mary Lou Bohn (now President of Titleist Golf Balls), and Fordie Pitts III did something remarkable: they walked.

Day after day, week after week, they walked practice round fairways with nearly 100 PGA Tour and LPGA Tour players. Their pitch was simple: “Hit this new Pro V1, compare it to your current ball, and tell us what you think.”

The response was overwhelming. Since that Vegas victory, players using Pro V1 models have won more than 4,000 tournaments across all worldwide professional tours and 47 men’s major championships.

Today, the Pro V1’s continued dominance is owed to what Courtney Engle, manager of mechanical engineering at Titleist, calls the R&D department’s mantra: “We might have something good, but how can we make it better?”

“It’s the only thing we think about,” said Mike Madson, Vice President of Golf Ball Research and Development.

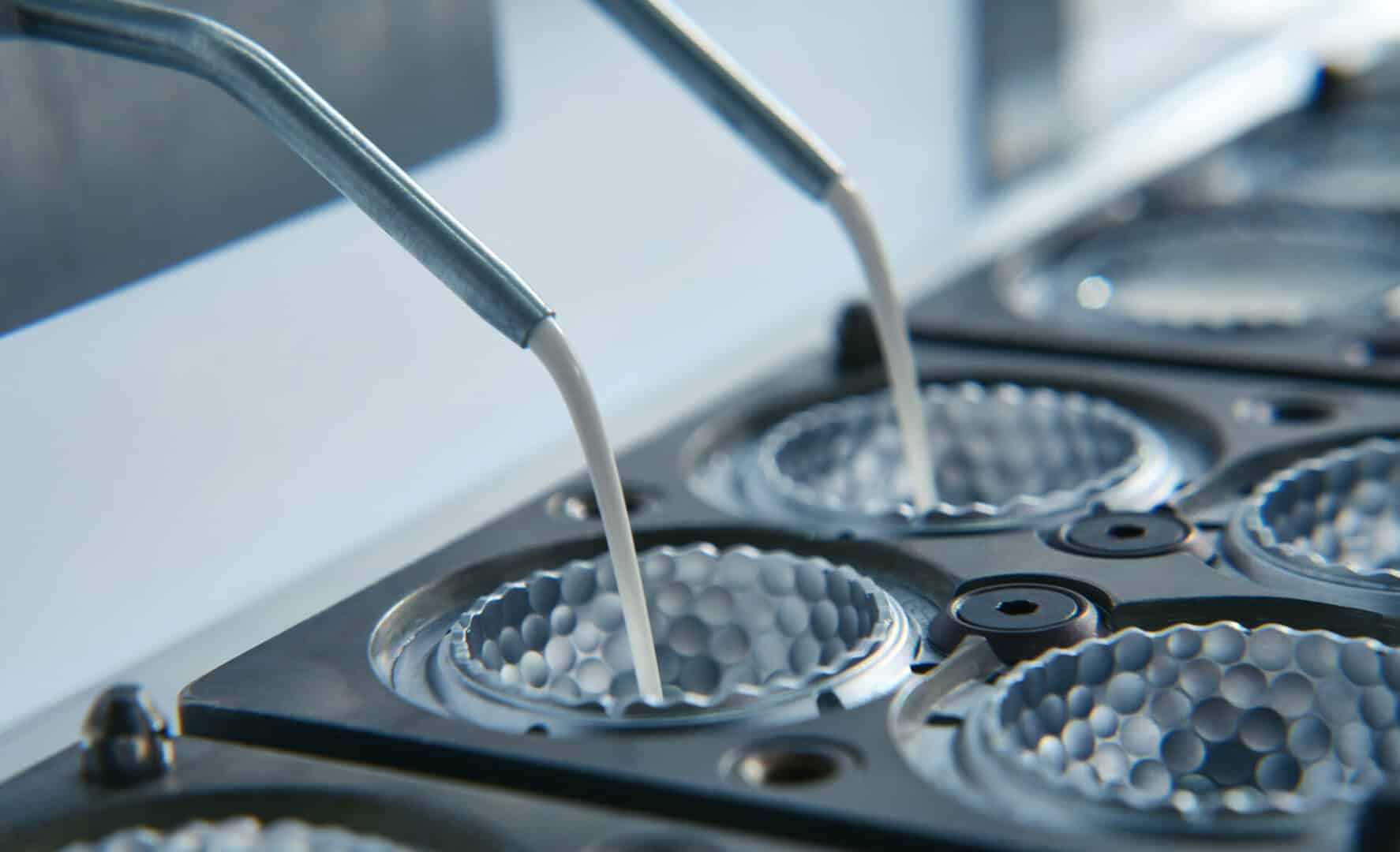

The 2025 Pro V1 and Pro V1x—the 14th iteration—has been in development for more than two years. Engineers test, fine-tune, re-test, tweak, scrutinize, and re-test again. They might build a hundred prototypes a year. None reach PGA Tour players until they meet rigid standards set by Titleist’s testing robots.

“We have to make it and break it,” the engineers say. It’s painstaking work that thrills the 75+ associates in Titleist’s Golf Ball R&D department, who proudly call themselves “nerds.” Madson refers to Engle as a “super nerd”—a badge of honor she wears with a brilliant smile, especially when discussing optimized edge angles of dimple configurations.

Everything happens within an 11-mile radius in Massachusetts. Titleist designs and builds the cavities for the proprietary urethane covers. They build and own the robots and launch monitors. As Rich Daprato, Director of Testing, puts it: “We make the tools in our toolbox.”

Fordie Pitts III, who started as a club fitter 30 years ago, now connects ball-makers with players at nearly three dozen PGA Tour events annually. He’s still out there walking practice rounds, gathering feedback, listening. Because in an age of Zoom calls and text messages, Pitts knows the magic happens face-to-face.

One Missed Putt, Endless Excellence

There’s a beautiful symmetry to this story. Phil Young’s engineering philosophy—if it works, take it apart to find out why—lives on in every Titleist engineer who asks, “How can we make it better?”

The Pro V1 is proof of that. One missed putt led to an X-ray. An X-ray led to a company. A company led to a philosophy. And that philosophy led to a golf ball that has dominated the sport for twenty-five years and counting.

The 2025 Pro V1 has arrived, continuing a story that began with curiosity on a putting green ninety-five years ago. Titleist engineers don’t build endings—they only build better beginnings.

And it all started because Phil Young refused to accept a missed putt without an explanation.